Bulk metallic glass Global market size and Key Producers

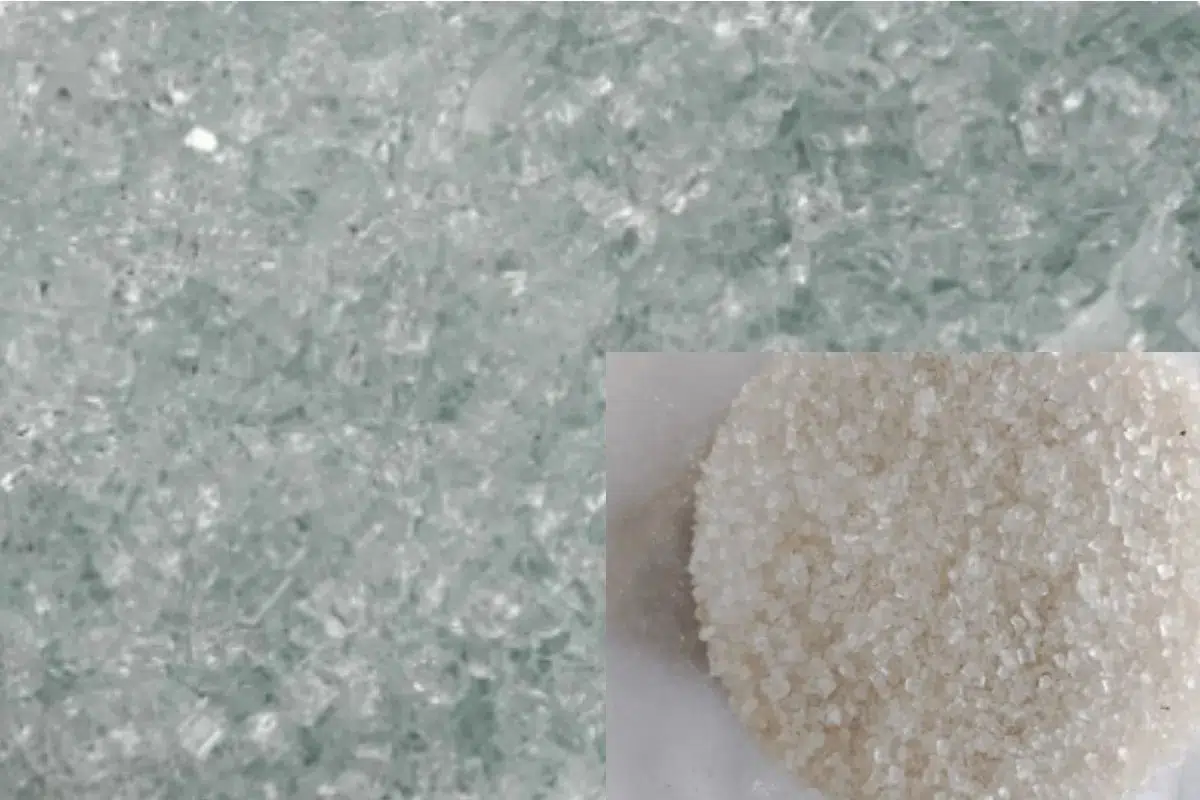

Bulk Metallic Glass (BMG), also known as amorphous metal, has been a fascinating development in materials science, combining the properties of both metals and glasses. With its unique molecular structure and impressive properties like high strength, corrosion resistance, and elasticity, BMG has become increasingly valuable across various industries. This article delves into the bulk metallic glass market, covering its current size, major producers, manufacturing processes, and applications, all of which shape the future of this remarkable material.

Table of Contents

The Bulk Metallic Glass Global Market Size

The global bulk metallic glass market has experienced steady growth over the past decade due to the increasing demand for high-performance materials. As of 2024, the Bulk metallic glass global market size is estimated to be valued between $80 million and $100 million, with an anticipated compound annual growth rate (CAGR) of around 10 – 15% over the next five years. Growth is driven primarily by the expanding applications of BMG in industries such as electronics, medical devices, automotive, and aerospace, where durability, elasticity, and corrosion resistance are crucial.

The Asia-Pacific region holds a significant share of the bulk metallic glass market, with countries like Japan, China, and South Korea leading in production and consumption. North America and Europe are also major contributors, with strong R&D investments in BMG technology for high-tech industries. The market’s growth trajectory is expected to remain positive as these regions continue to invest in the development and commercialization of BMG across emerging industries, making this a lucrative sector for manufacturers and investors alike.

Bulk Metallic Glass Producers

The production of bulk metallic glass involves complex manufacturing processes, and only a handful of companies specialize in this material. The leading bulk metallic glass producers include:

- Materion Corporation – Based in the United States, Materion is a one of the leading bulk metallic glass producers mainly in advanced materials, and it produces bulk metallic glass for various applications, including aerospace and electronics. The company revenue is mainly segmented as below.

Performance Materials: This segment focuses on beryllium and non-beryllium alloy systems, engineered parts, and beryllium hydroxide. In 2023 and 2022, Performance Materials accounted for 45% and 38% of the company’s total net sales, respectively.

- Beryllium oxide (BeO) can be used as a component in certain glass formulations, particularly in specialized optical and scientific glasses. Bulk glasses containing beryllium compounds are sometimes utilized in environments that demand high thermal stability and excellent transmission of ultraviolet light.

Electronic Materials: This segment specializes in advanced chemicals, microelectronics packaging, and various metal products used in semiconductors, displays, and other applications. Electronic Materials generated 48% and 55% of total net sales in 2023 and 2022, respectively

Precision Optics: This segment designs and produces thin film coatings, optical filters, and assemblies for various industries, including life sciences, aerospace and defense, and consumer electronics. Precision Optics contributed 6% of net sales in both 2023 and 2022

Other: This segment represents unallocated corporate costs and does not directly relate to specific materials or products. It accounted for less than 1% of total net sales in 2023 and a negligible amount in 2022

- Hitachi Metals, Ltd. – A leader in materials technology and bulk metallic glass producers, Hitachi Metals manufactures a variety of BMG alloys, focusing on applications in automotive, electronics, and industrial equipment.

- The company has a strong focus on developing new BMG alloys with improved properties, such as higher strength, better corrosion resistance, and enhanced formability.

- Hitachi Metals offers a range of BMG products, including rods, plates, and custom-shaped components.

- Heraeus Holdings is a major bulk metallic glass producers, particularly known for its expertise in specialty glasses. Heraeus produces high-purity optical glasses used in various applications, including – Cameras and lenses, Microscopes and telescopes, Medical devices, Laser technology, and Optoelectronic devices.

- Heraeus is a leading producer of high-purity quartz glass, which is essential for industries such as Semiconductor Manufacturing, Telecommunications, and Solar energy. Lighting.

- Eutectix LLC is one of the leading bulk metallic glass producers that specializes in the production of bulk metallic glass (BMG) alloys, also known as amorphous glass-forming alloys. Eutectix manufactures a variety of zirconium-based BMG alloys. They offer these alloys in various forms, including rods, tubes, and plates.

- These BMGs are used in various applications, such as Medical devices, Aerospace components, Automotive parts, Sporting goods, and Electronics.

- Glassimetal Technology Inc. is among the leading bulk metallic glass producers focuses on developing and manufacturing bulk metallic glasses (BMGs), also known as glassy metals. Glassimetal has developed a range of proprietary metallic glass alloys, including GlassiNickel, GlassiZirconium, GlassiSteel, GlassiGold, and GlassiPlatinum.

- Glassimetal’s materials have potential applications in various sectors, including Aerospace, Medical, Electronics, and Automotive.

These companies invest heavily in research and development to create customized BMG alloys that meet specific industry needs, driving innovation and competition within the bulk metallic glass market.

Bulk Metallic Glass Produce Method

The unique properties of bulk metallic glass are largely due to its non-crystalline structure, which differs significantly from traditional metals. Bulk metallic glass manufacturing process involves a manufacturing process that prevents crystallization, resulting in a material with an amorphous structure that imparts high strength, elasticity, and corrosion resistance. Here’s a closer look at the bulk metallic glass manufacturing process:

- Alloy Selection and Composition

The first step in bulk metallic glass manufacturing process is selecting the right metal alloys. Common elements in BMG include zirconium, titanium, copper, nickel, and aluminum. These alloys are chosen for their ability to form a stable amorphous structure, which requires careful balancing of the alloy’s chemical composition. - Rapid Cooling Process

The core of bulk metallic glass manufacturing process is the rapid cooling or “quenching” process. In traditional metal casting, molten metal cools slowly, allowing atoms to form a crystalline structure. However, in BMG manufacturing, the molten alloy is cooled at an extremely fast rate, often over 1,000 degrees Celsius per second. This rapid cooling “freezes” the atoms in a disordered state, preventing crystallization and resulting in an amorphous or glass-like structure. - Injection Molding

For bulk production, BMG is often shaped using injection molding. The alloy is melted and injected into a mold, where it rapidly cools and solidifies into a desired shape. Injection molding allows for precise shaping and minimal material wastage, making it ideal for industries that require intricate designs. - Surface Treatment and Finishing

After molding, BMG materials may undergo additional surface treatments, such as polishing or coating, to enhance properties like wear resistance and aesthetic appeal. This step is particularly important for consumer electronics and medical devices, where surface quality is essential.

The manufacturing process of BMG is highly specialized, requiring precision and control at every stage. Although complex, this process is key to producing bulk metallic glass with its characteristic strength, flexibility, and corrosion resistance, setting it apart from conventional metals.

Also Read

Applications of Bulk Metallic Glass

Thanks to its unique combination of properties, bulk metallic glass has a diverse range of applications across multiple industries. Here are some of the most notable uses:

- Consumer Electronics is one of the fastest-growing applications of bulk metallic glass is in consumer electronics. BMG’s strength, durability, and resistance to scratching make it ideal for producing casings and frames for smartphones, tablets, and wearables. Its amorphous structure also allows for intricate designs, which appeal to manufacturers aiming for sleek, premium aesthetics in devices. Companies like Apple have even explored using BMG for durable device casings, which underscores its appeal in high-end electronics.

- Bulk metallic glass 3d print, and it’s gaining attention as a revolutionary material in additive manufacturing. The unique atomic structure of BMG allows it to be molded and shaped without the limitations of crystalline grain structures found in traditional metals. This makes it ideal for 3D printing complex geometries with high precision and minimal material waste. Bulk metallic glass 3d print leverages the material’s strength, elasticity, and corrosion resistance, producing parts that are both lightweight and durable, which is especially beneficial in industries like aerospace, medical devices, and consumer electronics.

- Medical Devices

The medical industry benefits greatly from the biocompatibility and corrosion resistance of bulk metallic glass. BMG is used in surgical instruments, implantable devices, and medical equipment where strength and durability are essential. Its non-corrosive properties make it suitable for devices that need to withstand the harsh environments of the human body, including orthopedic implants and dental applications. - Automotive and Aerospace

In both the automotive and aerospace industries, lightweight yet strong materials are essential for improving fuel efficiency and safety. Bulk metallic glass offers high strength-to-weight ratios, making it ideal for various components in these sectors. In aerospace, BMG can be used in structural parts, fasteners, and gears, where its high elasticity and wear resistance are crucial. The automotive industry also uses BMG for parts that experience high wear and tear, such as gears and engine components. - Sporting Goods

The elasticity and strength of bulk metallic glass have also found applications in the sports industry. BMG is used in golf clubs, tennis rackets, and other sporting equipment where strength, impact resistance, and precise weight distribution are essential. For example, BMG-based golf clubs provide increased power and accuracy due to the material’s unique mechanical properties. - Industrial Machinery

Industrial applications of bulk metallic glass include manufacturing molds, dies, and other components that require hardness and wear resistance. BMG’s durability allows it to withstand the high-stress environments typical in industrial settings, improving the longevity of equipment and reducing the need for frequent replacements. - Energy Storage and Batteries

In the energy sector, BMG materials are being explored for battery technologies and energy storage systems. The high elasticity and strength of BMGs are beneficial in batteries where flexible structures and resistance to degradation are needed, particularly in applications like electric vehicles.

Future Outlook and Market Opportunities for Bulk Metallic Glass

The future of the bulk metallic glass market looks promising, with technological advancements and increasing demand across various industries driving growth. As industries continue to seek materials that offer superior performance over traditional metals, BMG is well-positioned to meet this demand. Future developments in manufacturing processes, such as advanced injection molding techniques and the introduction of more cost-effective alloy compositions, are expected to reduce production costs, further broadening BMG’s applicability.